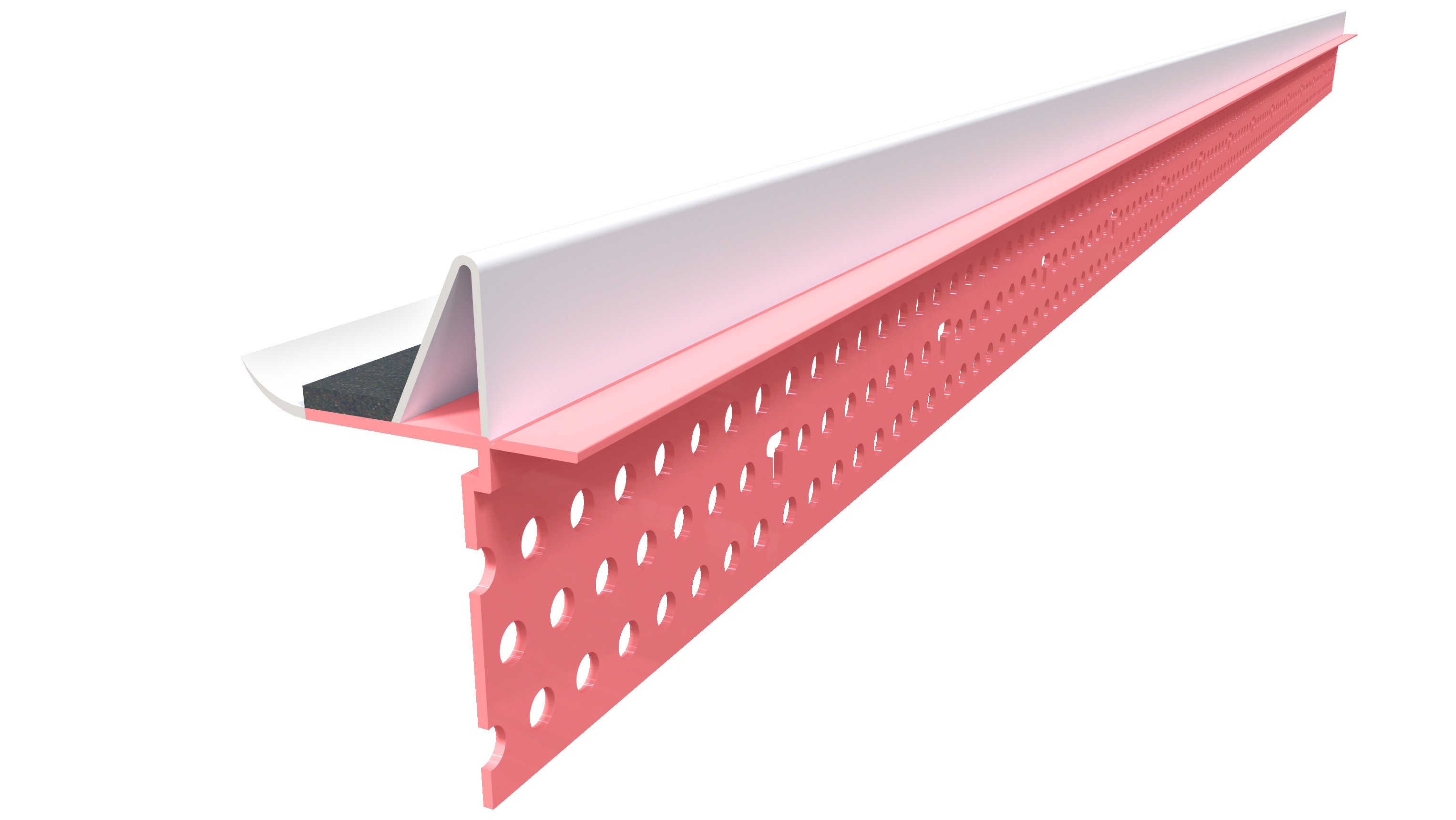

Ever since we rolled out our family of fire rated drywall accessories, we’ve been hearing from finishers, project managers and architects from all over about how they’ve helped save them time and headaches. They’re far easier to install than fire caulks and sprays, last practically forever and help protect walls from damage due to structural movement — what’s not to love? But one question we get from time to time has caused some to scratch their heads: why are our firestopping solutions pink in color?

The light reddish color of our groundbreaking code compliance solutions is unique among our collection of corner beads, almost all of which are tinted white. So why mix things up here? The short answer is that it’s another time-saving tactic — the pink color makes them easier for inspectors to spot, allowing them to do their jobs faster and your crews to move on to the next task that much more quickly.