Drywall 101: Prevent Drywall Cracks

Drywall is so widely used in nearly every type of building due to its ease of use, low cost, and overall durability — its price-to-quality and price-to-safety ratios just can’t be beat. But, of course, drywall is only actually going to be effective as a time- and money-saving option if the installation is executed well. Mistakes or lack of foresight during installation may result in costly repairs over time. Proactively taking steps to prevent drywall cracks reduces risks that can affect your bottom line, avoiding that call from an unhappy client asking you to come back a few weeks after completing a job to do repairs.

What can be even more costly to the drywall contractor are the indirect expenses of cracked finishes — losing customers or tarnishing a good reputation — making it more difficult to obtain jobs in the future. For example, drywall installed in the summer may crack due to environmental fluctuations in the winter. In these cases, you might not be called to do free or reduced-cost repairs (as when the cracking occurs immediately) because you might not be called at all. A client who sees cracking many months after the job was finished may conclude that the drywall was installed poorly to begin with. In such a case, the customer will probably call someone else to do the repairs — now you’ve not only lost the potential for repeat business, but the high value of a referral as well.

Cracks can form for a variety of different reasons. Depending on the location of the crack, it may be caused by building movement, environmental factors or lack of foresight on the part of the professional who installed it. In the following sections, we’ll break down everything you need to know based on the location of the crack (ceilings versus walls) for most kinds of cracking, then explore possible causes as well as solutions to prevent drywall cracks altogether.

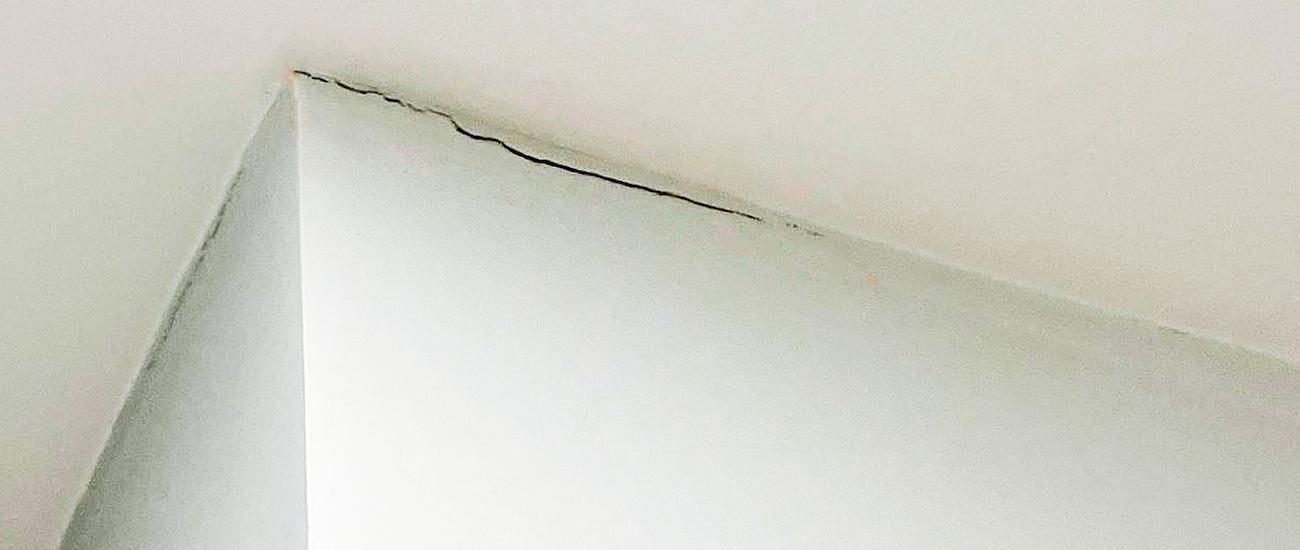

Ceilings

TRUSS UPLIFT

Many new and recently built structures use trusses, which are manufactured assemblies that transfer load to the outside walls, allowing an open interior with few, if any, load-bearing interior walls. While they are a great solution for modern design and often cheaper than stick-built roof framing, trusses are subject to a particular problem called uplift.

Truss uplift is where the bottom cord of the truss is subjected to significantly different environmental conditions (moisture/temperature) than the rest of the truss. When this happens, usually during the winter months, the bottom chords, buried in heavy insulation, stay dry and contract, while the rest of the truss assembly does not. In fact, the upper part of the truss may expand as it is exposed to high humidity. This causes an upward expansion that pulls the drywall up with it, causing cracking at the interior ceiling corners.

Solution: Install a backing angle designed to minimize inside corner movement and thus prevent truss uplift. Trim-Tex’s Truss Backing Angle is installed along the length of the wall, and holds the drywall inside corner together while allowing the trusses to move as needed. The drywall should be attached to the truss 18 inches out from the backing angle to allow for movement without cracking. Learn more about what truss uplift is and how to avoid this kind of damage here.

BUILDING DEFLECTION

Like truss uplift, building deflection results from movement of the building itself, except this time we’re usually talking about multi-story structures. Deflection is when a load on the building, over time, gradually deforms any number of building materials (joists, trusses, rafters, concrete decks, et al.), causing movement that can easily cause cracks in your finish. Most often, you’ll find these cracks at your head-of-wall joints.

Solution: Any multi-story building, especially those that occasionally take an unexpected load or deal with widely variable loads, should consider preventative measures to avoid cracking from deflection. Traditionally, that meant some kind of caulk, but sealants come with their own set of setbacks — it’s tricky to apply evenly, and will become less and less flexible through the years. When it eventually hardens and shrinks back, it can cause its own set of cracks.

Instead, we’d recommend using a Wall Mounted Deflection Bead (pictured above) in these head-of-wall gaps, which comes with a flexible gasket that can compress under load. This way, the bead spares the less flexible materials (like concrete and drywall) from having to bear the burden of building movement. This gasket, unlike caulk, remains flexible for the lifetime of the wall assembly. Similarly, our family of code compliance solutions accommodate deflection while also providing added benefits like preventing the passage of fire, smoke and/or sound.

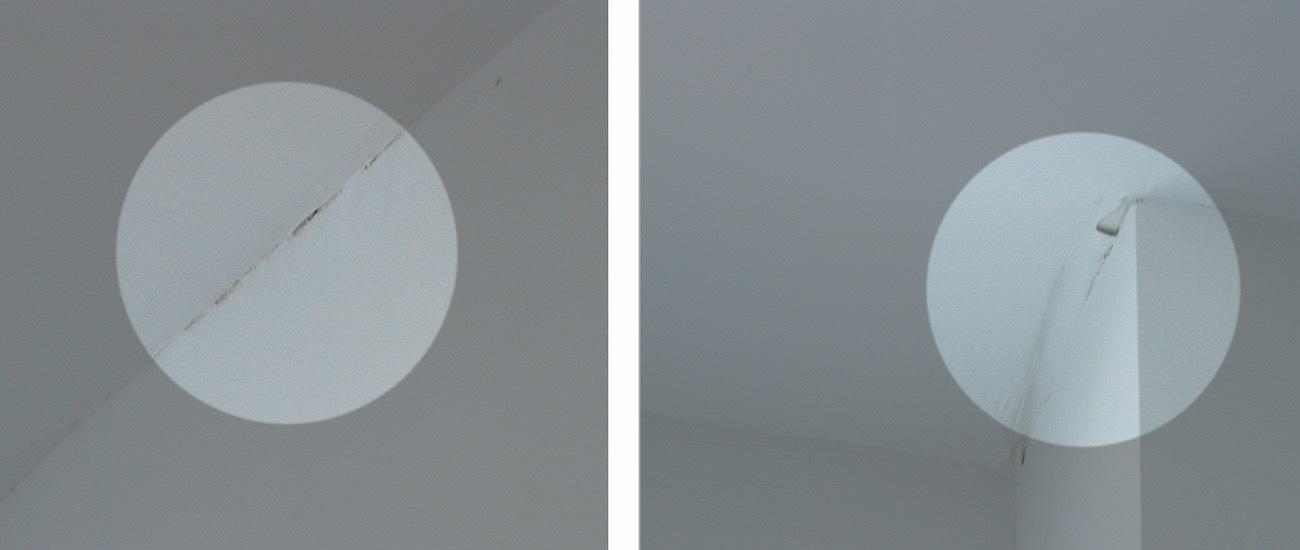

VAULTS & OFF-ANGLES

Like the problem of truss uplift, vaults can crack when lumber shrinks on both sides of the peak, adding stress to the inside peak. Cracking can also result from improper application of joint compound in an inside corner angle. Meanwhile, you can simply paper tape off-angles, but off-angles are prone to poor framing and hanging, and cracks should be expected eventually.

Solution: You’ll need a highly malleable solution that can flex, expand and contract along any inside corner, no matter the angle. You’ve got a lot of options here, but your best bet in most situations would be our versatile Magic Corner solution, which offers a flexible center channel, allowing for installation at any angle and controlled movement up to 3/8 of an inch.

A vinyl solution like Magic Corner also prevents you from having to worry about paper scuffing or blistering, but if you’re a fan of paper-covered solutions in these areas like these, you have got to try Trim-Tex's latest innovation, Fast Edge Roll.

Walls

EXPANSION

Just as in ceilings, walls can suffer from differential expansion in response to environmental concerns. As a result, in long runs of drywall, 15 feet or longer, it is important to leave a gap between sheets to allow them to expand and contract freely to accommodate fluctuations in the ambient environment and prevent drywall cracks.

However, these gaps must be bridged by expansion joints that control the movement and create a unified surface.

Solution: The best expansion joints to prevent drywall cracks are made of vinyl — the 093V Expansion Joint and its less noticeable counterpart, Hideaway Expansion Joint — which resists denting and remains permanently flexible, limiting wear-and-tear and the need for repairs. As we saw with deflection beads, we’ve also got a solution that allows you to meet the needs of an expansion joint while simultaneously meeting building codes for cutting off fire and smoke, all in a single easy-to-use solution: the Fire Rated 093V Expansion Joint, also known as 093X-V (pictured above).

TRAFFIC

While it may seem obvious, it's worth mentioning that one of the leading causes of cracked drywall, especially in commercial and multi-family environments, comes from natural wear-and-tear. As clients come and go or tenants move in with all their possessions, it is easy for them to bump into a corner and leave it cracked or dented.

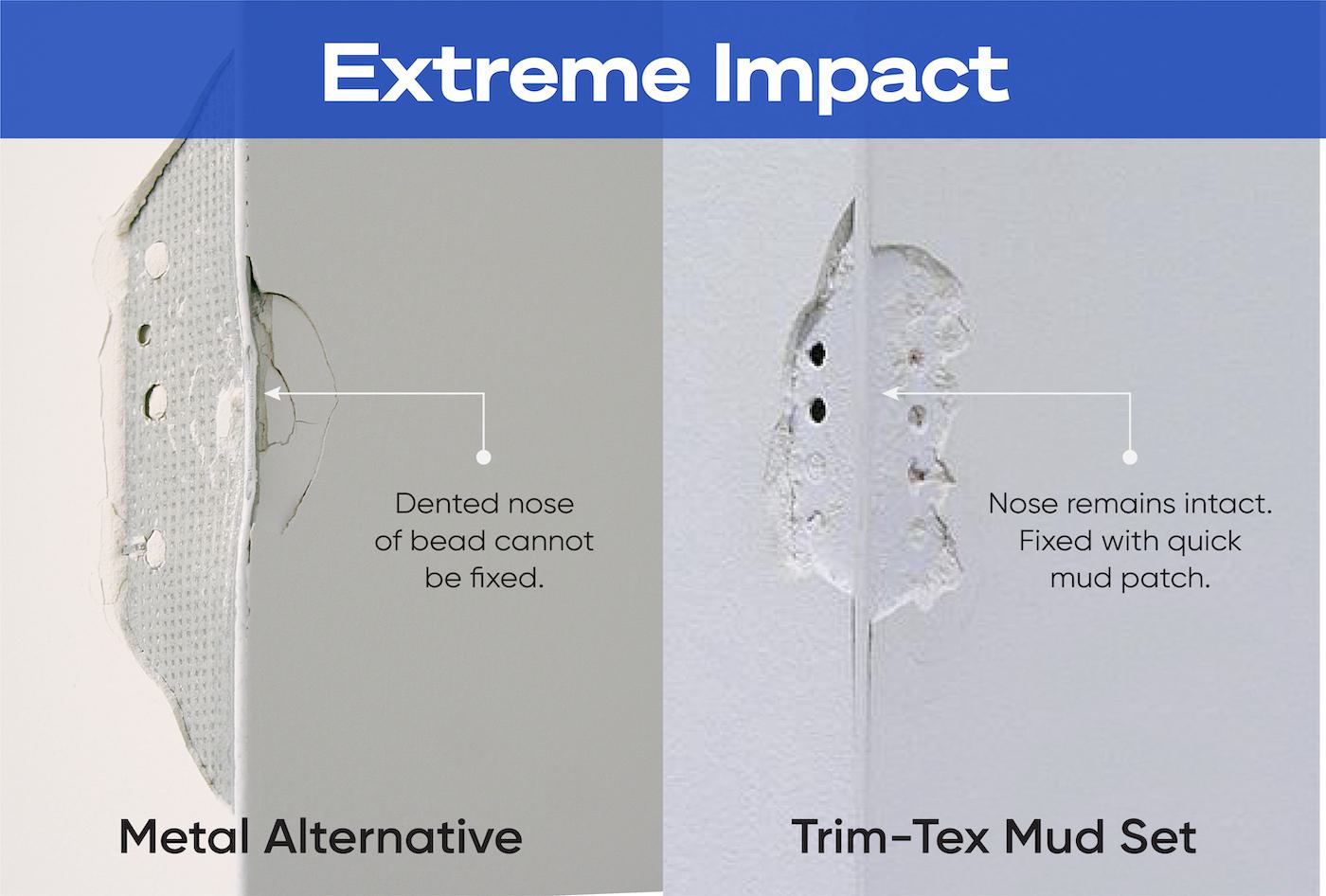

Solution: Traditional metal corner beads offer some protection against these kinds of impacts because they offer a fair amount of tensile strength. However, the downside of metal beads is that once deformed, they do not spring back, so any dents or damage will be permanent. Alternatively, vinyl corner beads offer a higher degree of resistance to damage, with a flexibility that allows them to bounce back. This reduces the need for repairs, as vinyl can deform temporarily in response to impact and then return to its original shape. Nine times out of 10, if repair is required, a simple mud patch will have it looking as good as new.

AGAINST BUILDING SUBSTRATES

Adding to the complexity of solving problems related to building movement — especially expansion — is the fact that materials expand and contract at every single edge, including internal ones. That means that there is also the potential for expansion (and cracking!) at any place where different materials meet: doors, windows and wherever drywall meets concrete.

Solution: For these cases, you should consider products that not only seal against the environment, but offer the flexibility required to keep doors, windows, etc. functioning correctly and with no unsightly cracking around the edges. Where the drywall meets a window, as seen in this image, the flexible apex gasket on our Super Seal Tear Away bead makes it the perfect solution to create a clean finished edge that offers protection for the drywall as well as a perfect, permanent seal.

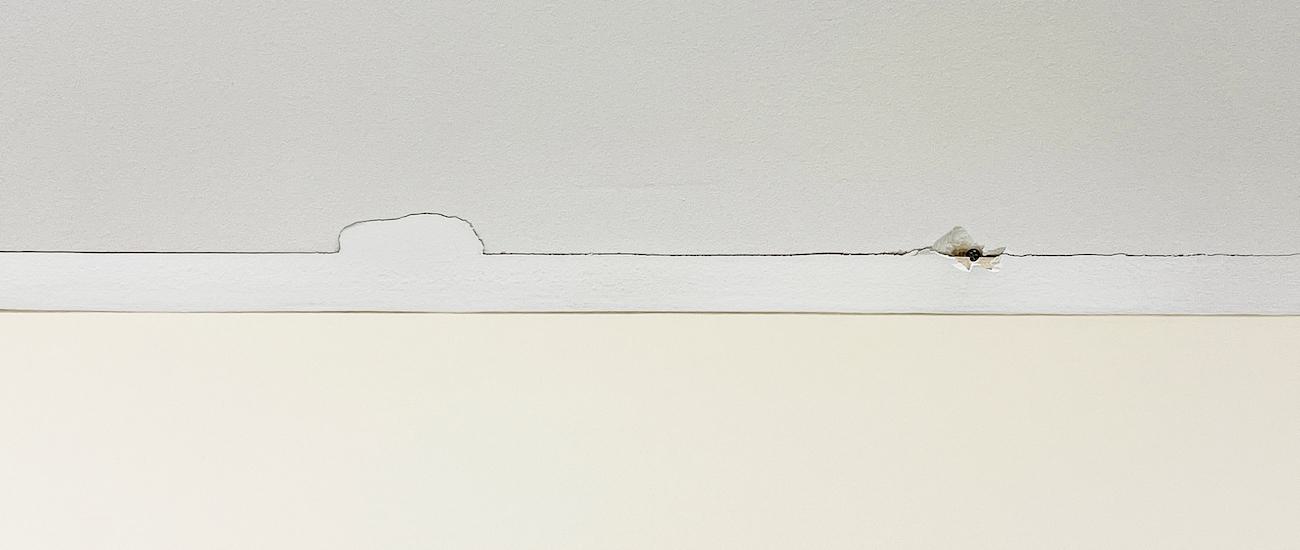

BUTT JOINTS

Butt joints, where two pieces of drywall meet, are areas easily susceptible to cracking. It's ridiculously easy for less experienced drywallers to cause these kinds of cracks, but even true pros are no strangers to problems arising here.

Solution: To minimize cracking, do your best to place your butt joint where they are the least exposed to movement. For instance, notch your drywall around doors and windows instead of breaking drywall at these movement-prone areas. Next, leave a 1/8-inch gap between your boards — do not fit them tight against each other. This 1/8-inch gap give the boards room to move, so they won’t be as likely tear the tape or break the mud.

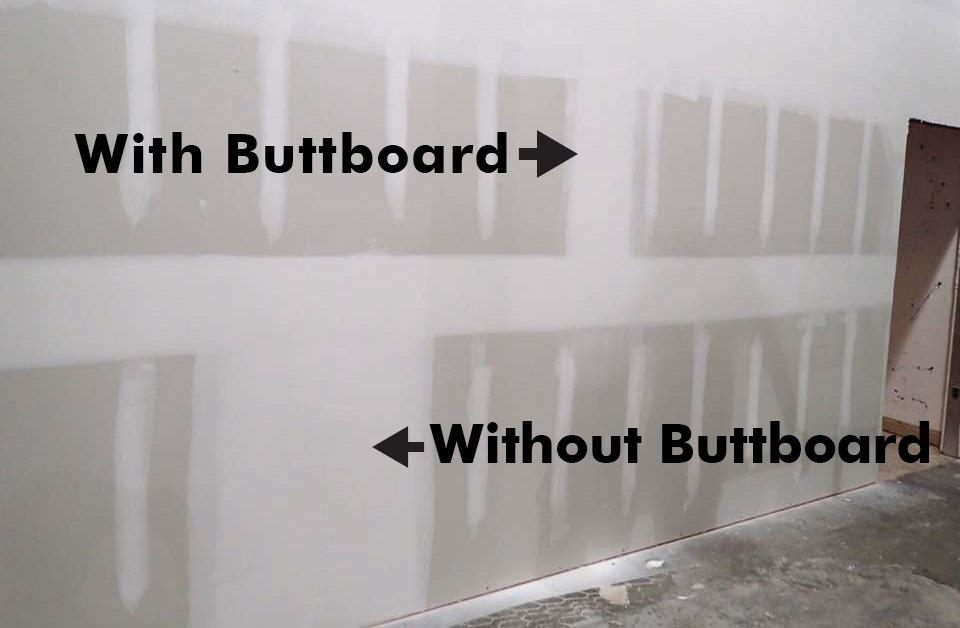

Limiting the amount of mud needed to feather the butt joint also reduces the likelihood of cracking. Cracking often occurs when the mud on the surface dries faster than the mud underneath. Buttboard is a product that creates an easy-to-fill recess, similar to a factory edge. While it may look like a standard piece of OSB, the board is cut with edges that taper off toward the middle, which allows the board to pull in the drywall edges. This recess requires less mud to fill than feathering a traditional butt joint that breaks on a stud, which often forms a hump that must be feathered, costing you significantly more mud and more time.

A drywall finisher’s ability to prevent drywall cracks over time places them ahead of the pack, and is the mark of a true pro. For more pro tips like these, Trim-Tex is here to help — every week, we publish something new to help drywallers of all skill levels. Never miss an update by hitting the button below to sign up for our monthly newsletter!

Trim-Tex in Your Inbox

Subscribe to our e-newsletter for monthly tips, news, case studies and updates