Drywall 101: The History of Corner Bead Materials

Why have people used drywall corner beads through the years? It’s simple: while the front surface of a gypsum board may be resilient, the edges are anything but. They’re brittle and fragile, and even a little impact can do some serious damage. A corner bead is a layer of protection along those edges, and has been a fixture of construction and the finishing trade ever since the gypsum board’s introduction in 1916, originally made of plaster.

But the corner bead wasn’t a one-and-done innovation. Craftspeople have never stopped tinkering with the concept practically since day one, making them more resilient, more adaptable and from a wide variety of materials. After drywall rolled out onto the market, it became pretty common pretty quickly — according to AWCI's Celebrating 100 Years of Industry Growth, half of all new homes featured drywall by 1955, and just a year after that, 56 percent of residential construction was using it. Strong, sturdy corner beads became more sought-after during drywall’s rapid rise, and with that demand came a greater supply of options for corner bead materials.

To help make sense of how these indispensable pieces of interior construction advanced through the years, let’s take a quick trip through the history of corner bead materials!

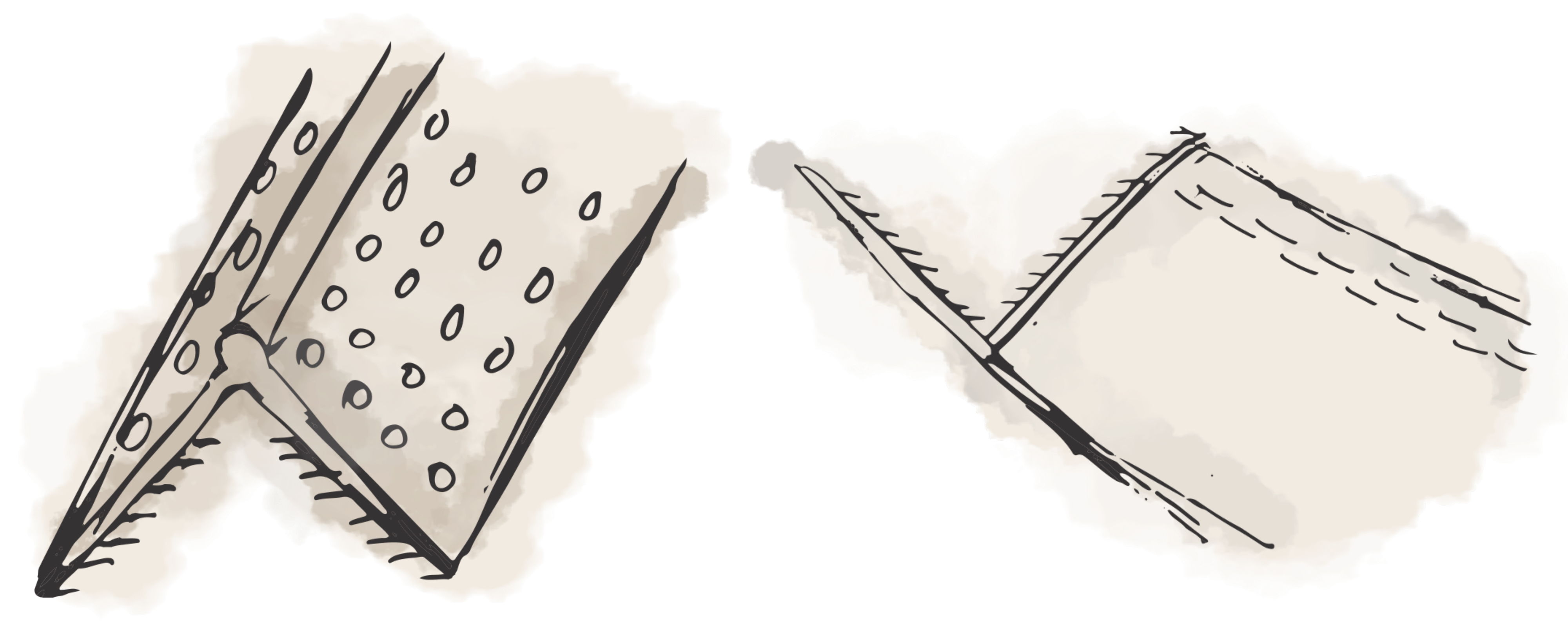

1950s: Metal

The fast upsurge of drywall in construction in the ’50s saw a similar upsurge in the corner bead material that is still the most commonly used today: metal. Thin sheets of galvanized metal, rolled into shape from flat stocks, became appealing for their strength and resistance to impact. Unfortunately, however, if you hit a metal corner bead with enough force, it will be permanently deformed. Metal beads are installed by using nails, screws or a crimper.

Key benefits: Metal corner bead is cheap and available just about anywhere as the current industry standard

Key limitations: It’s prone to irreparable damage, even at the warehouse and in transit, creating a lot of waste and cash thrown out the window

1970s: Vinyl

The next major innovation in corner bead materials also breathed life to Trim-Tex Drywall Products over 50 years ago. Although metal corner beads were popular, many contractors in the finishing trade were looking for alternatives — from materials that were more resilient, and importantly, less dangerous to work with. One such contractor came to Trim-Tex founder Joseph Koenig, Sr. — who, at the time, owned a vinyl siding business — and asked for a PVC alternative to the metal J Beads that would cut his hands up when installing them. This led to Koenig extruding the first rigid vinyl J Bead for the drywall industry, which he sold out of the back of his truck; many more profiles were soon to follow. Vinyl beads are installed with staples or glue before mudding.

Key benefits: Much higher durability than metal (in addition to being rust-proof), with a ton of different shapes to choose from for just about any job

Key limitations: It can be harder to find the specialty trims of some vinyl drywall corner beads, especially compared to your basic metal bead

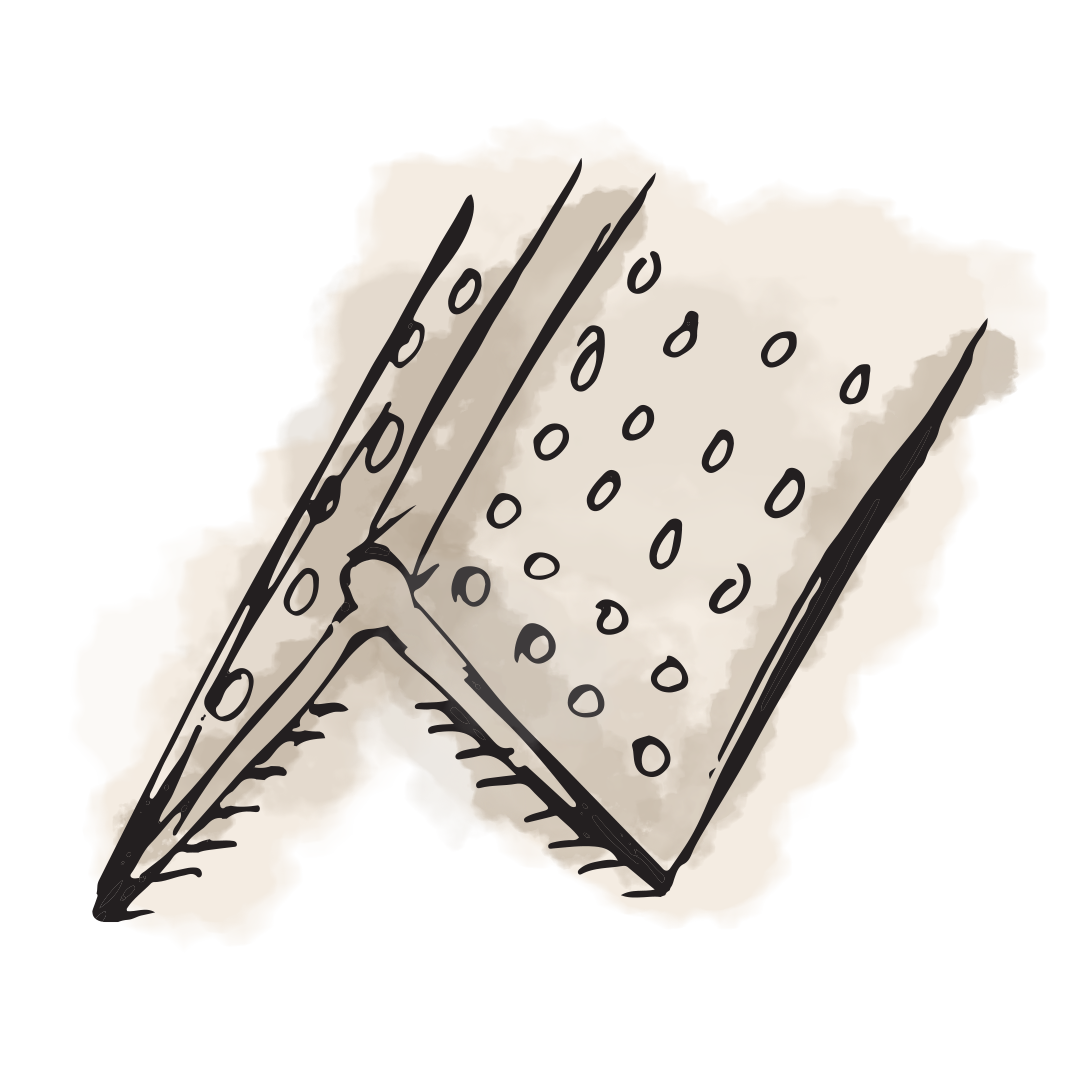

1990s: Paper Faced Metal

Eventually, some advancements were made to the standard “Shiny 90” metal corner bead. Through covering the metal with a thin layer of paper, drywall finishers were able to reduce corner cracking and increase the bead’s bond to the drywall. No more mechanical fasteners — these beads are simply installed with a few coats of mud and a roller, or by running it through a hopper.

Key benefits: No edge cracking, and an easier installation process

Key limitations: While an improvement, paper faced metal still has many of the drawbacks of metal — it’s more easily damaged, difficult to repair and inflexible.

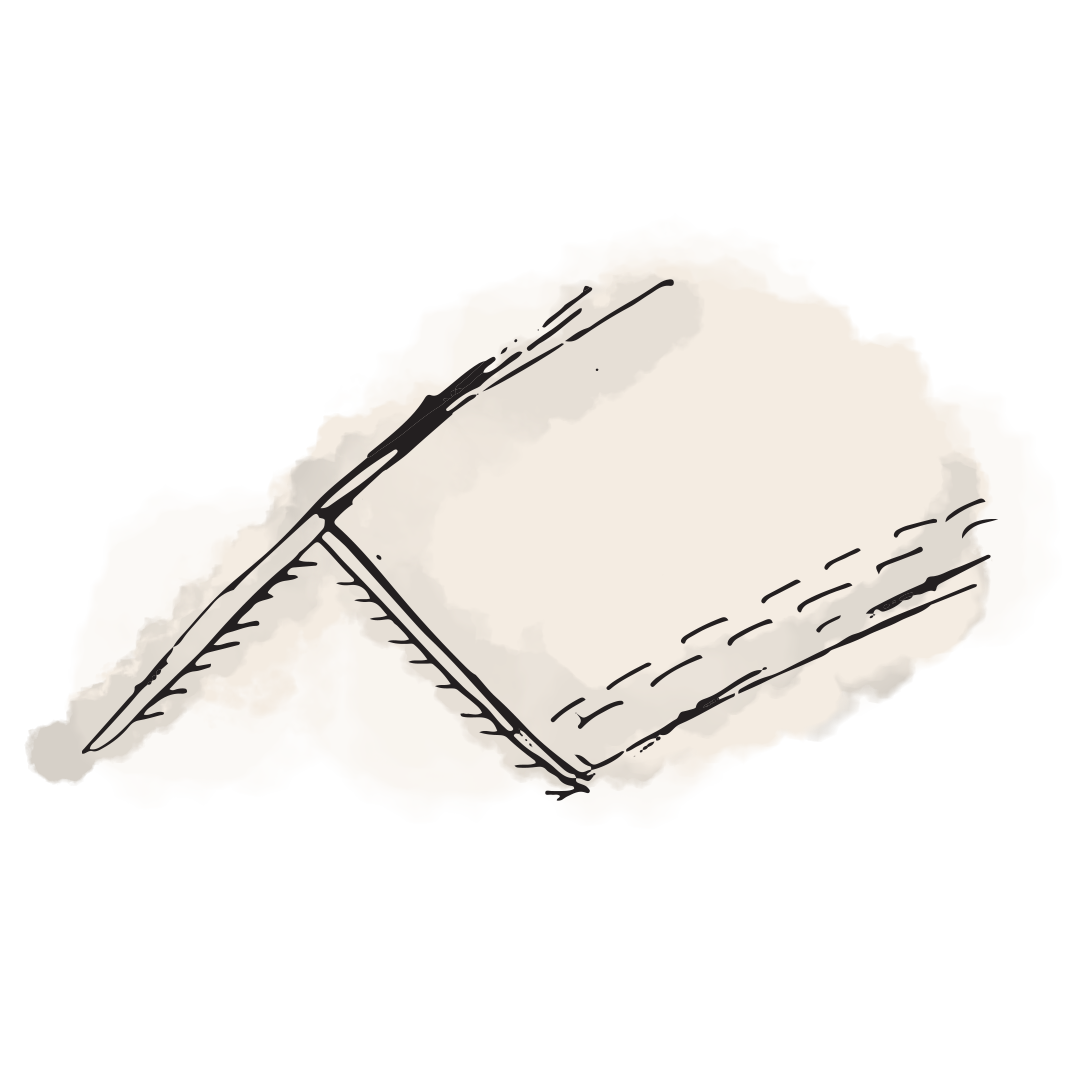

2000s: Paper Faced Composite

The new millennium saw the rise of a new form of bead — taking the advantages of paper faced metal and ditching metal’s drawbacks — consisting of a layer of paper around plastic. Aimed at a higher-end clientele, with a high price point to match, paper faced composite corner beads were a hit among its fans. These beads, too, are installed fairly easily by eliminating mechanical fasters, with a hopper or by applying mud directly to the drywall with a compound tube.

Key benefits: Less mud to coat and finish than previous corner bead materials, and is easy to install

Key limitations: It has a pretty limited range — corners and L’s only — yet it’s the most expensive option on the market

TODAY: Mud Lock Vinyl

In the last decade, Trim-Tex has broken new ground in our line of over 200 drywall solutions, introducing cutting-edge vinyl technology that does away with mechanical fasteners like staples and glue, while using its patented Mud Lock Technology to form the strongest bond to the drywall you can get. First came Mud Set Bead, then, last year, the twin innovations of Fast Edge®, which is fully vinyl, and Fast Edge Paper, which is vinyl prelaminated with paper. All these varieties of Mud Lock vinyl beads are installed quickly and simply, by running them through a hopper or applying compound to the drywall.

| Key benefits of Mud Set Bead: This thing’s a tank — it’s the most durable corner bead ever made in the history of corner bead materials, with the strongest bond to the drywall out there Key limitations of Mud Set Bead: It takes a good amount of mud to coat and finish |

| Key benefits of Fast Edge & Fast Edge Paper: These high-performance beads are also quite durable and tightly bonded to the drywall, but with the fastest installation (while using less mud) than anything else on the market. Key limitations of Fast Edge & Fast Edge Paper: They are pricier than some of your other options on the market |

The history of corner bead materials shows that the book is never finished being written on these dynamic drywall accessories. Even in the last year since we rolled out the Fast Edge family of beads, for instance, we didn’t rest on our laurels — we introduced the first-ever line of fire and sound rated drywall accessories. You can count on imaginative drywall designers to continue to evolve and create new solutions for the finishing trade, and you can count on Trim-Tex to never stop innovating along the way.

If you want to get your hands on the most advanced corner beads in the history of drywall, locate a trusted dealer near you below!

Find Your Local Dealer

Trim-Tex beads are flying off the shelves at a dealer near you. Snag a box or a truckload of your favorite corner profiles today.